|

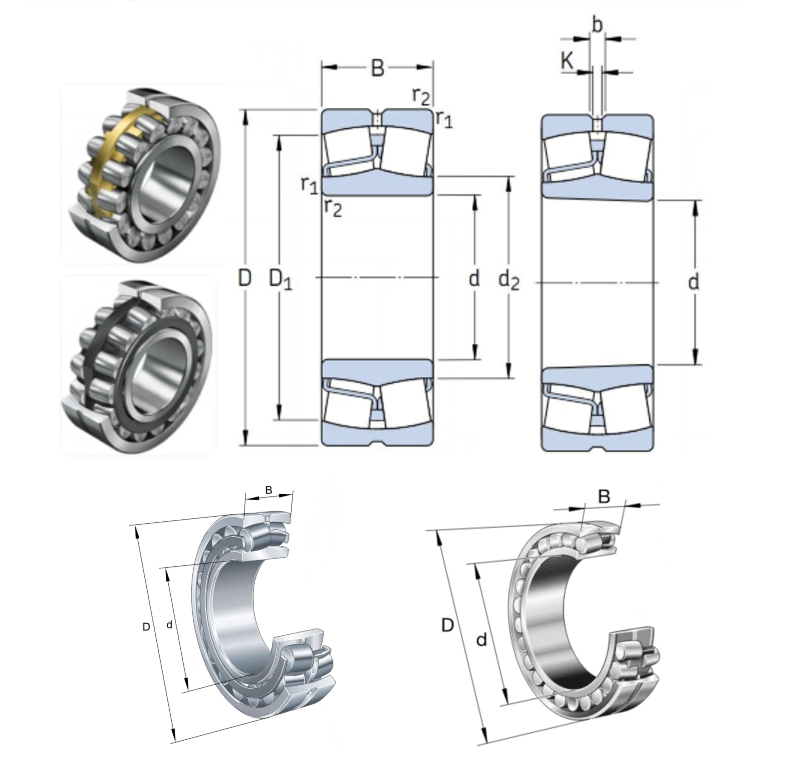

Spherical roller bearing

Collect

Self aligning roller bearings have two rows of rollers, which mainly bear radial loads and can also withstand axial loads in any direction. They have high radial load capacity and are particularly suitable for working under heavy loads or vibration loads, but cannot withstand pure axial loads. The outer raceway of this type of bearing is spherical, so its centering performance is good and can compensate for coaxiality errors. There are two rows of symmetrical spherical rollers, with the outer ring having a shared spherical raceway and the inner ring having two raceways tilted at an angle to the bearing axis, which have good centering performance. When the shaft is bent or installed unevenly, the bearing can still be used normally. The centering performance varies depending on the size series of the bearing. Generally, the allowable centering angle is 1-2.5 degrees. This type of bearing has a large load capacity, and in addition to bearing radial loads, the bearing can also withstand axial loads acting in both directions, with good impact resistance. Generally speaking, the allowable working speed of self-aligning roller bearings is lower. Self aligning roller bearings are divided into two different structures based on the cross-sectional shape of the rollers: symmetrical spherical roller and asymmetric spherical roller. Asymmetric self aligning roller bearings are early products mainly used for maintenance services of the host. When designing new hosts, symmetrical self aligning roller bearings are rarely used. The internal structure has been comprehensively improved and optimized, and compared with early produced self aligning roller bearings, it can withstand greater axial loads. This type of bearing has a lower operating temperature and can adapt to higher speed requirements.

|