|

Tapered roller bearing

Collect

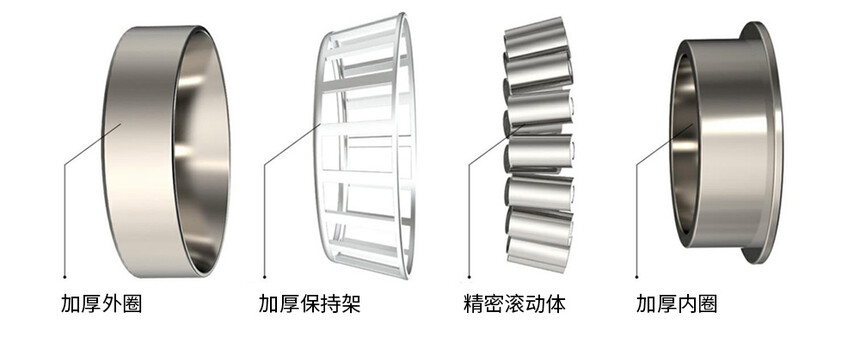

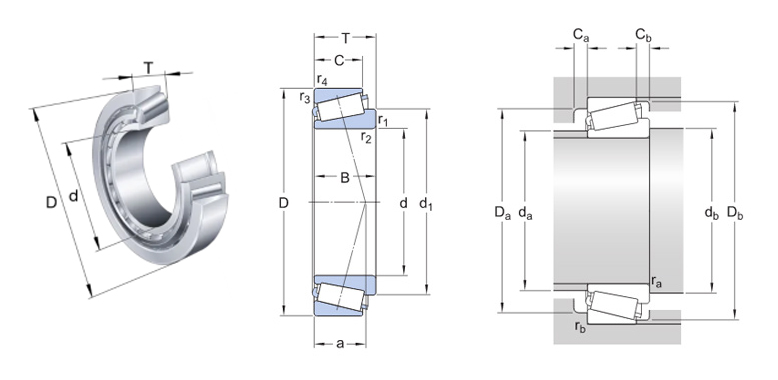

The tapered roller bearing belongs to the separated type bearing, and both the inner and outer rings of the bearing have tapered raceways. The inner ring and a group of tapered rollers are enveloped by a basket shaped cage to form an inner ring component. The outer ring can be separated from the inner ring component, and the outer ring and inner component can be interchanged and used interchangeably. The bearing is designed to adapt to combined loads, that is, radial and axial loads acting simultaneously. The extension lines of the raceways intersect at the same point on the bearing axis to achieve true rolling. Therefore, it has low friction torque during operation. The axial load capacity of tapered roller bearings increases with the increase of contact angle. The size of the contact angle is related to the calculation coefficient, and the larger the value, the larger the contact angle. Single row tapered roller bearings can withstand radial loads and axial loads in a single direction. The ability of axial loads depends on the contact angle, that is, the outer raceway angle. The larger the angle, the greater the axial load capacity. When the bearing is subjected to radial load, an axial force component will be generated. Therefore, when another bearing that can withstand reverse axial force is needed for balance, compared with angular contact ball bearings, the bearing capacity increases and the ultimate speed decreases.

|